Services

With over 20 years of business experience, you can trust ACIA to solve any indoor air quality issue within your facility. From the start, indoor air quality sampling was a backbone of the business, as ACIA carries a Certified Indoor Air Quality Professional accreditation. Whether it is an air quality complaint by an employee, suspected mold, production quality issues, or certifying a clean room, ACIA can identify problem areas and make recommendations to reduce or eliminate the problem.

In 2002, ACIA introduced in-house services while gaining additional certifications and accreditation from multiple industry leading trade organizations. These certifications and a long standing commitment to their customer base distinguishes ACIA from the competition by staying ahead of ever changing industry practices and technology.

Today, the company offers a variety of services to data centers, schools K-12, universities, retail, commercial / industrial, manufacturing, and healthcare facilities. For more detailed information on our service offerings, please click the respective box below.

View Our Services

Duct Cleaning

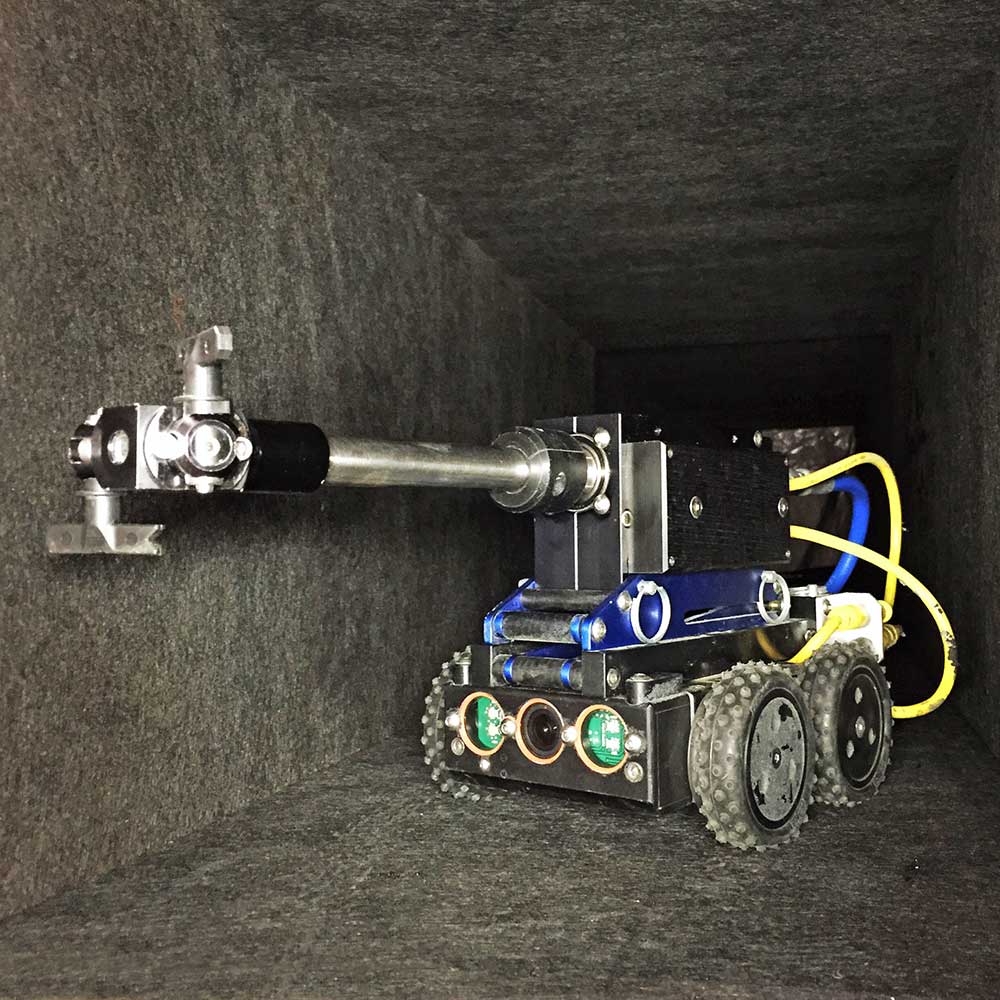

Robotic Duct Sealing

Video Duct Inspection

Indoor Air Quality Testing

Dust Collector Service & Replacement Filters

Fire & Smoke Damper Inspections

Commercial Dryer Vent Cleaning

Filter Change Out Service

Mold Remediation

Antimicrobial Fogging & Unit Sterilization